Services

Focusing on the details is what AMC does best. We take our client’s abstract ideas through a comprehensive design process, helping them realize their vision in a way that is efficient to fabricate and robust enough for long-term operation. AMC’s advanced equipment and experienced team manufacture custom products of the highest quality.

Precision Machining

Investing in state-of-the-art equipment is our top priority at AMC, because that’s how we deliver the highest quality products to our customers. Our CNC’s utilize 3-, 4- and 5-Axis Precision Milling Machines and Turning Centers to process any job so that the quality remains constant from the first product to the last.

Our equipment can handle:

- CNC Milling

- CNC Turning

- Saw Cutting

- Precision Inspection Equipment

- Support Equipment

Fabrication and Installation

Our fabricators and certified welders have the experience to take on any kind of project—large or small—with the know-how to deliver, assemble, and install onsite. No matter the size or type of material—even exotic metals—our clients come to us for custom, finished products all under one roof.

Our fabrication services include:

- Certified Welding (including AWSD1.1 and AWSD1.2 structural aluminum and steel, from 1/8″ to unlimited thicknesses)

- Tube Bending / Rolling

- Plate Bending

- Punching & Notching

- Painting / Powdercoating / Finishing

Waterjet

For whatever the project may require, AMC is equipped to cut any size and shape in a single step with our advanced waterjet cutting. Delicate or durable surfaces can be introduced into a finished product, allowing our clients the capability to create unique products with any raw material.

AMC’s waterjet department utilizes:

- 90,000 psi Waterjet cutting

- up to 5′ x 10′ surface

- Virtually any material

Design & Drafting

Our experienced designers can work with a client to flesh out their ideas into comprehensive mechanical drawings ready for fabrication. Because of our knowledge of the production process, we also provide expert consultation for alternative designs that can increase fabrication efficiency and lower costs.

Our team is skilled in:

- 3D Modeling

- Conceptual Design

- FEA Analysis Software

- AutoCAD 2015

- Inventor

- Master Cam X7

- SolidWorks

Structural/Fabric Solutions

As part of the AMC family of companies, Las Vegas Awnings & Structures supports the needs of our clients looking for shade structures, awnings, cabanas, and more. This collaboration further increases the capability of our facility and the types of projects that also include fabric furnishings as part of the scope.

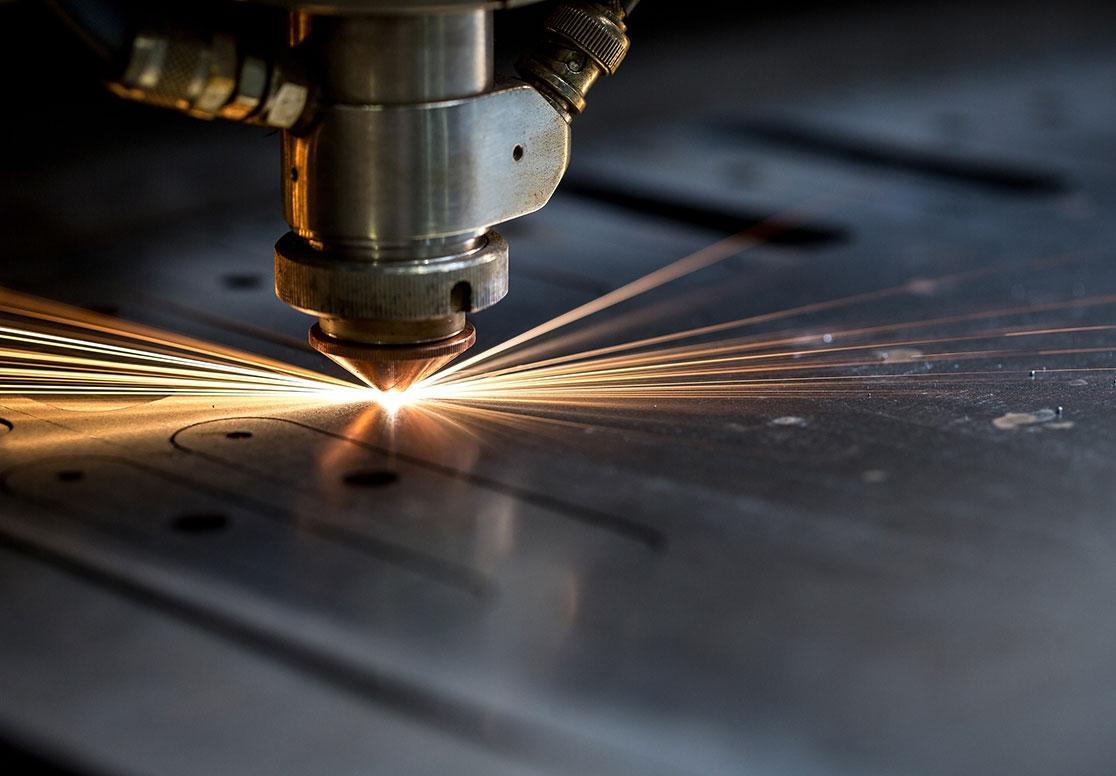

Laser Cutting

Laser cutting offers numerous advantages over traditional cutting methods, such as greater accuracy, faster cutting speeds, and the ability to cut complex shapes and patterns. It is commonly used in our manufacturing process, prototyping, and in the production of custom-made fabrication products.

AMC Fabrication offers the best laser cutting services in all of Las Vegas. Give us a call today for more information on laser cutting.

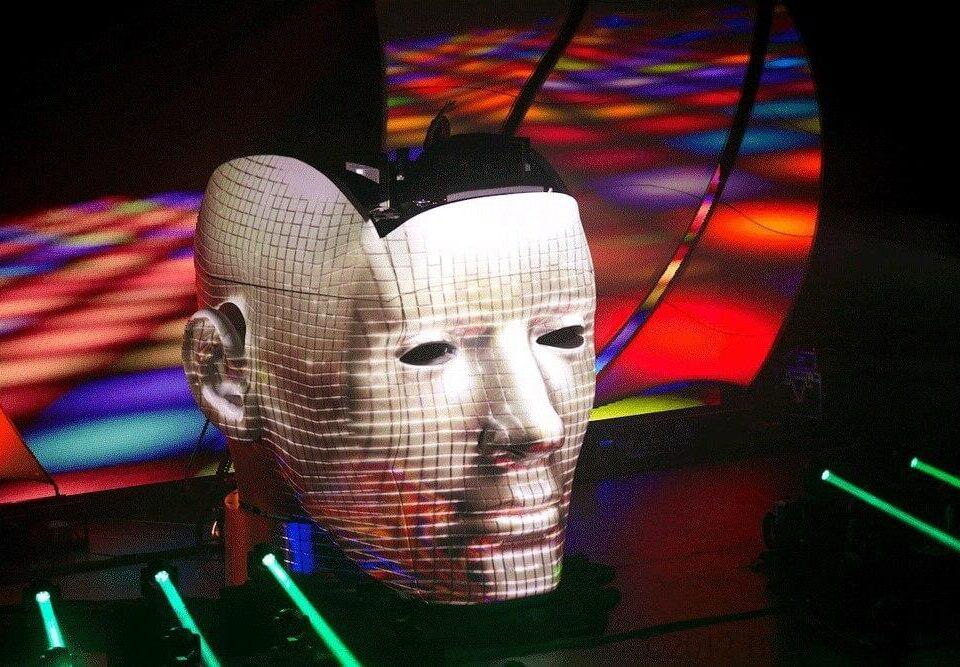

Mechanical Design

We focus on achieving simplicity while conceptualizing and constructing intricate mechanical systems. Our seasoned team is dedicated to developing robust designs that can withstand the rigors of the entertainment industry, all while maintaining an elegant integration into scenic elements

Project Management

We transform abstract concepts into tangible achievements. Whether we lead a team of consultants to integrate their systems or collaborate with our client’s in-house creative designers, we oversee every project facet, guaranteeing a successful build, installation, and operation.

Performer Flying Integration

When it comes to crafting specialty apparatus for flying performers and creating captivating moments in entertainment productions, AMC Fab rises to the occasion. With a wealth of experience garnered from managing shows with esteemed companies such as Cirque du Soleil, AMC Fab is dedicated to guaranteeing both performer and audience safety through the meticulous technical design of aerial props.Capability description

Spectacular

At AMC Fab, we craft the magic behind extraordinary show spectacles, where the audience remains blissfully unaware of the intricate workings. We seamlessly integrate complex show action equipment to craft unforgettable special effects that consistently astonish audiences